3in1 Laser Welding Cutting Cleaning Machine Operation Manual

Machine connection

The machine is connected to power, wire feeder and gas

The machine needs to be connected with gas, either Nitrogen or Argon, and the pressure of Nitrogen is 0.2 or 0.3

Water cooler, the temperature should be above 20 degrees.

Machine use

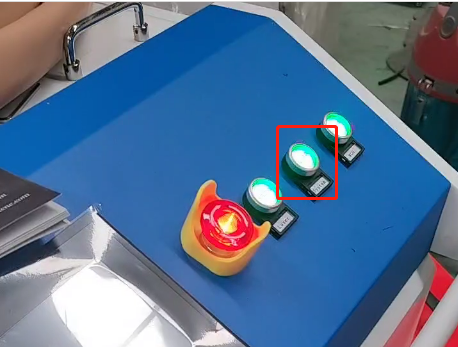

1. Start-up sequence:

start with the main power supply on the left, then the water cooler on the far right, and turn on the remaining 2 first, whichever one is fine.

2. Welding

When welding, use a wire feeder, and the wire feeding speed is 80 or 100. Turn off the wire feed when cutting and cleaning.

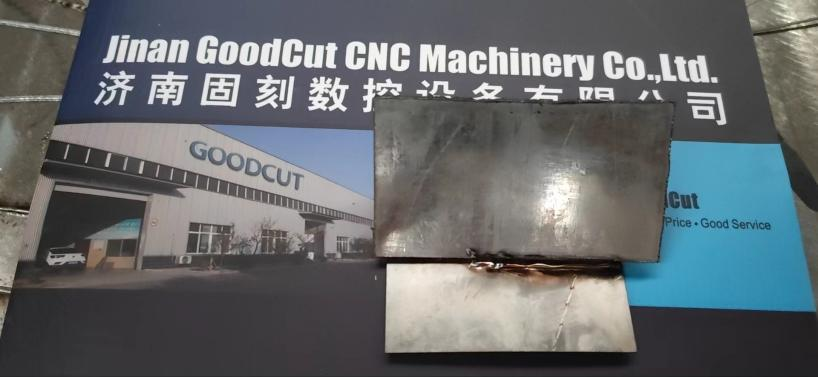

Gas connection is required. If the air pressure is too high, the silk will be blown away, the effect is as follows.

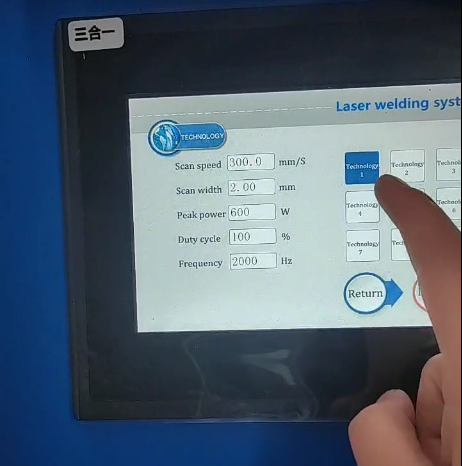

Set parameters. We will provide a parameter table.

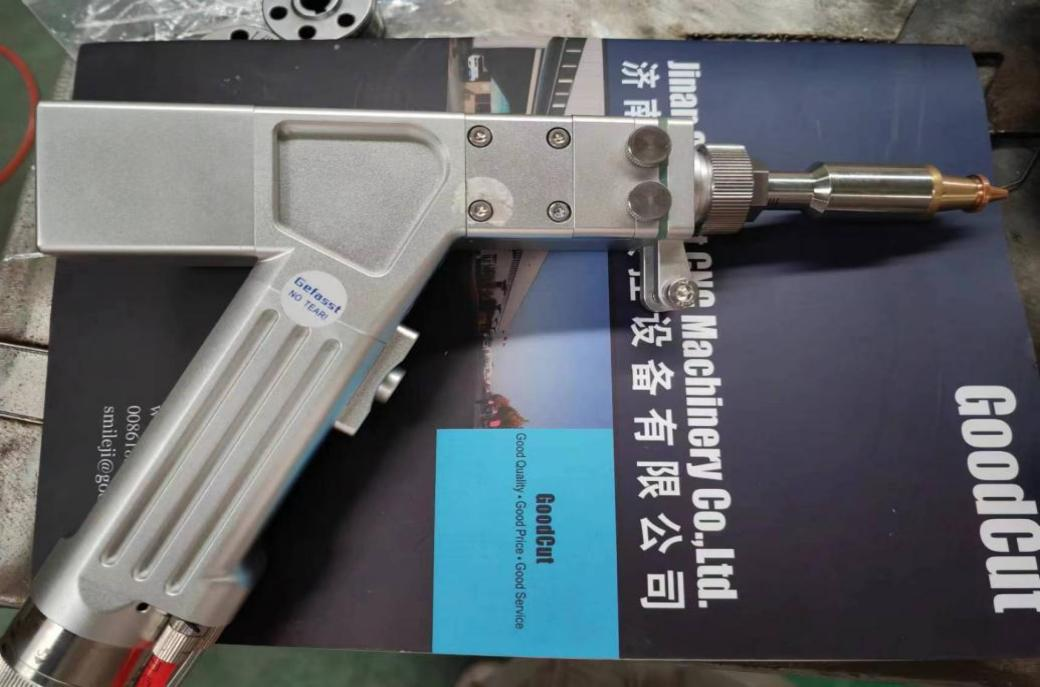

The appearance of the welding head.

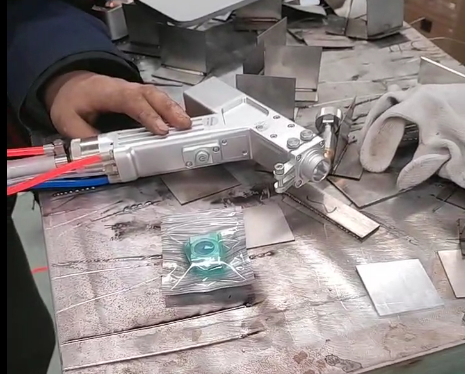

Welding machine work:

3. Welding and cutting:

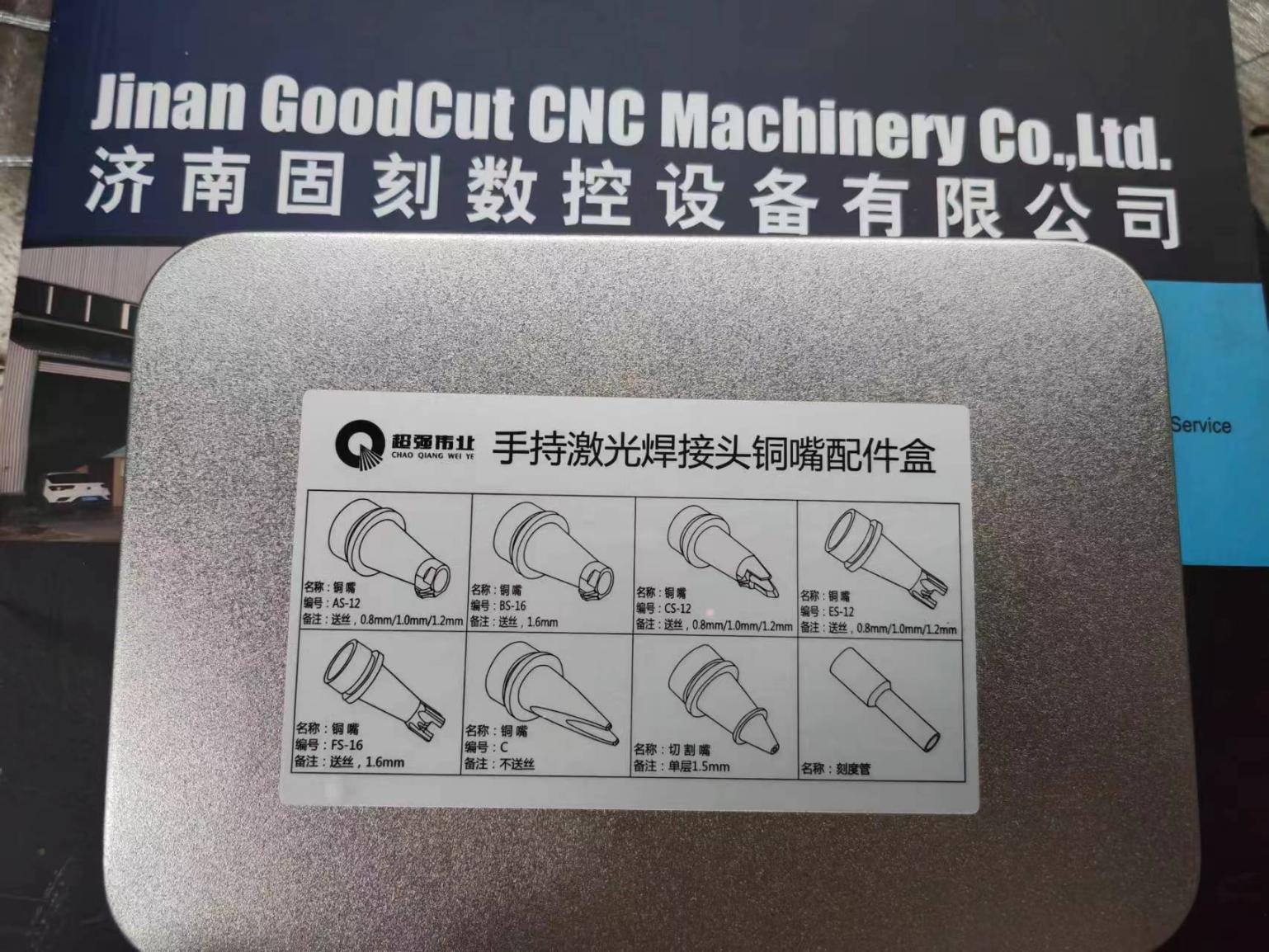

change the nozzle, unload the wire, and change the parameters.

Cutting parameters, we will provide parameter table

unloading wire

Change the cutting nozzle

The appearance of the replaced gun head

Turn off the wire feeder

4 Cleaning:

Change the head, unscrew the front one.

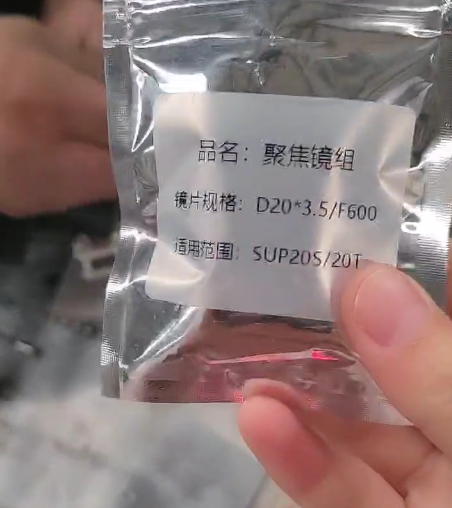

Change focus lens.

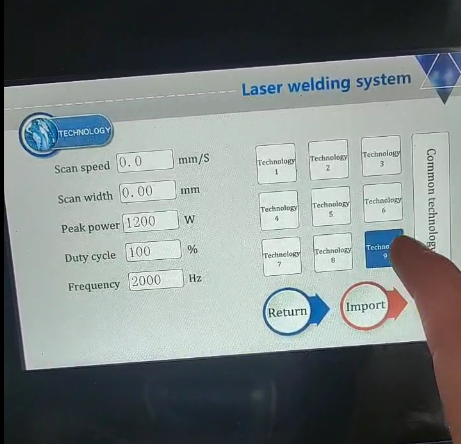

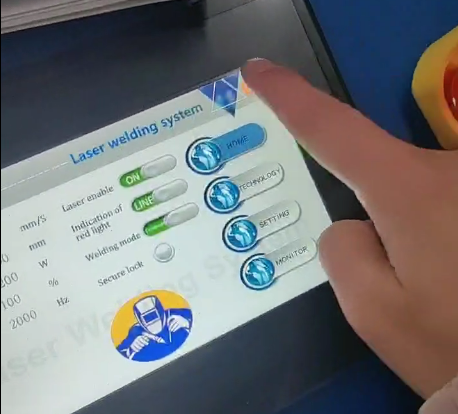

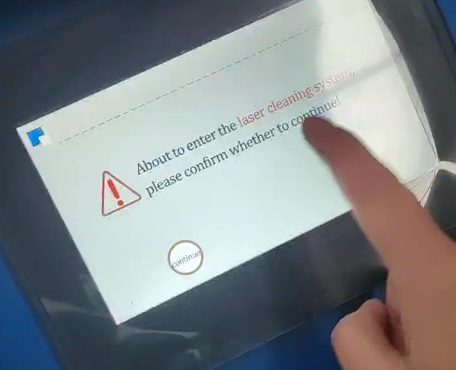

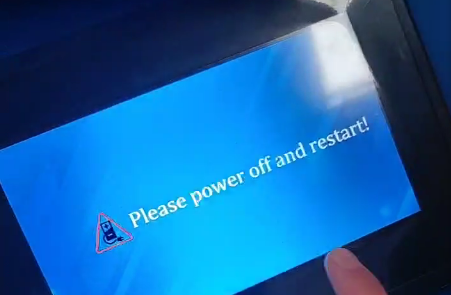

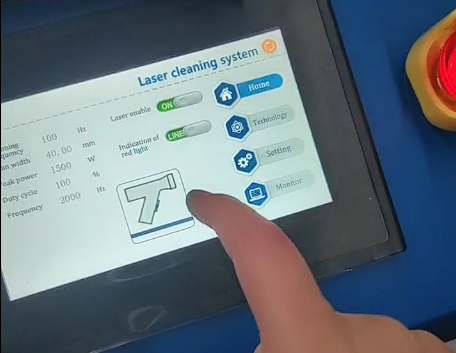

You need to put the system into cleaning mode, then shut down and restart.

Change focus lens

state of cleaning

Change the system, adjust the system to cleaned one, then shut down and restart

5 If the protective lens is broken, and you need to replace it, the operation is as follows.

function removeCommentId() {

$("#blog-reply-id").val(0);

$("#reply-remove").css('display', 'none');

}